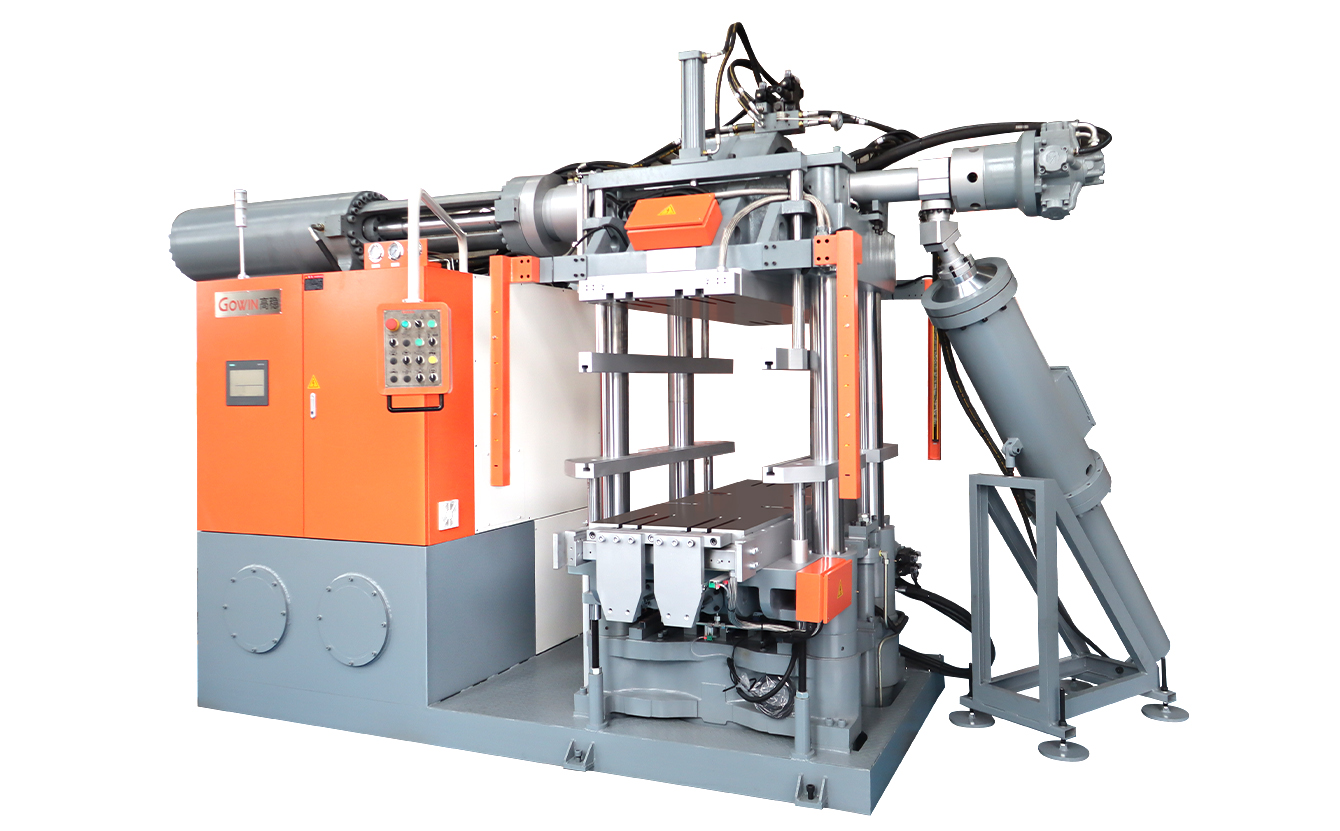

Ezweni lokudluliswa kwamandla nokusabalalisa, ukuphepha nokuthembeka kukagesi kubaluleke kakhulu. Ukuqinisekisa ukusebenza okuphezulu kanye nemishini ehlala isikhathi eside, abakhiqizi bathembele ezingxenyeni zekhwalithi ephezulu njengei-silicone insulatorsfuthiukubamba umbani. Kodwa ingabe wake wazibuza ukuthi lezi zingxenye ezibalulekile zenziwa kanjani? Impendulo ivela ku- zobuchwepheshe obuphambili:imishini yokubumba yomjovo we-silicone eqinile.

Kulesi sihloko, sizobhekisisa ukuthi imishini yokujova i-silicone yesimo esiqinile isebenza kanjani, nokuthi kungani ibaluleke kangaka ekukhiqizeni izivikeli eziqinile nezibambisi umbani ezivikela ingqalasizinda yethu kagesi.

Uyini Umshini Wokujova We-Silicone Wesifunda Esiqinile?

Umshini womjovo we-silicone wesimo esiqinile uwucezu olukhethekile lwemishini esetshenziselwa ukukhiqiza izingxenye ezenziwe ngerabha ye-silicone ye-viscosity ephezulu. Irabha ye-Silicone isetshenziswa kakhulu embonini yamandla ngenxa yezindawo zayo ezinhle kakhulu zokuhlukanisa ugesi, ukumelana nesimo sezulu, kanye nekhono lokumelana namazinga okushisa aphezulu.

Umshini usebenza ngokushisisa nokujova i-silicone yesimo esiqinile (i-high-viscosity) ekubunjweni, lapho upholisa khona futhi uqine ube esimweni oyifunayo. Le nqubo idinga ukunemba, njengoba i-silicone kufanele igeleze ngokulinganayo ekubunjweni futhi yakha izingxenye ezinokubekezelelana okuqinile, ukuqinisekisa ukuthi zihlangabezana nezindinganiso eziphakeme ezidingekayo zemishini yamandla.

Isebenza Kanjani Le Mishini?

1. Ukulungiselela kanye Nokuxuba:

Ngaphambi komjovo, irabha ye-silicone ixutshwa nama-ejenti okwelapha nezinye izithasiselo ukuze kuqinisekiswe ukuthi ihlangabezana nezinto ezidingekayo, njengokuvala ugesi kanye nokumelana nesimo sezulu.

2.Ukushisisa nokukhipha:

Izinto ze-silicone zibe sezishiselwa ezingeni elithile lokushisa, zehlise i-viscosity yayo ukuze ikwazi ukugeleza kalula ekubunjweni. I-silicone yesimo esiqinile ikhishwa ngesikulufu noma ngomshini wepiston emshinini womjovo.

3.Ukujova kumaMolds:

I-silicone eshisayo ijovwa ekubunjweni okunembayo lapho ithatha umumo wengxenye oyifunayo, njengesivikelo noma igobolondo elibamba umbani. Inqubo yokubumba ibalulekile ngoba izingxenye zidinga ukunemba okuhle kakhulu kwe-dimensional ukuze zisebenze kahle.

4. Ukwelapha Nokupholisa:

Uma i-silicone ijovwe esikhunjeni, ibhekana nenqubo yokwelapha (ukwelashwa kokushisa), okuqinisa impahla. Isikhathi sokuphulukisa kanye nezinga lokushisa kulawulwa ngokucophelela ukuze kuqinisekiswe ukusebenza kahle.

5. Ukwakhiwa kanye Nokuhlola:

Ngemva kokupholisa, ingxenye ikhishwa esikhunjeni. Ukuhlolwa kokulawula ikhwalithi kuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso ezidingekayo zokusebenza kukagesi, amandla emishini, nokuqina.

Kungani Imishini Yokujova I-Silicone Yesifundazwe Ibalulekile Embonini Yamandla?

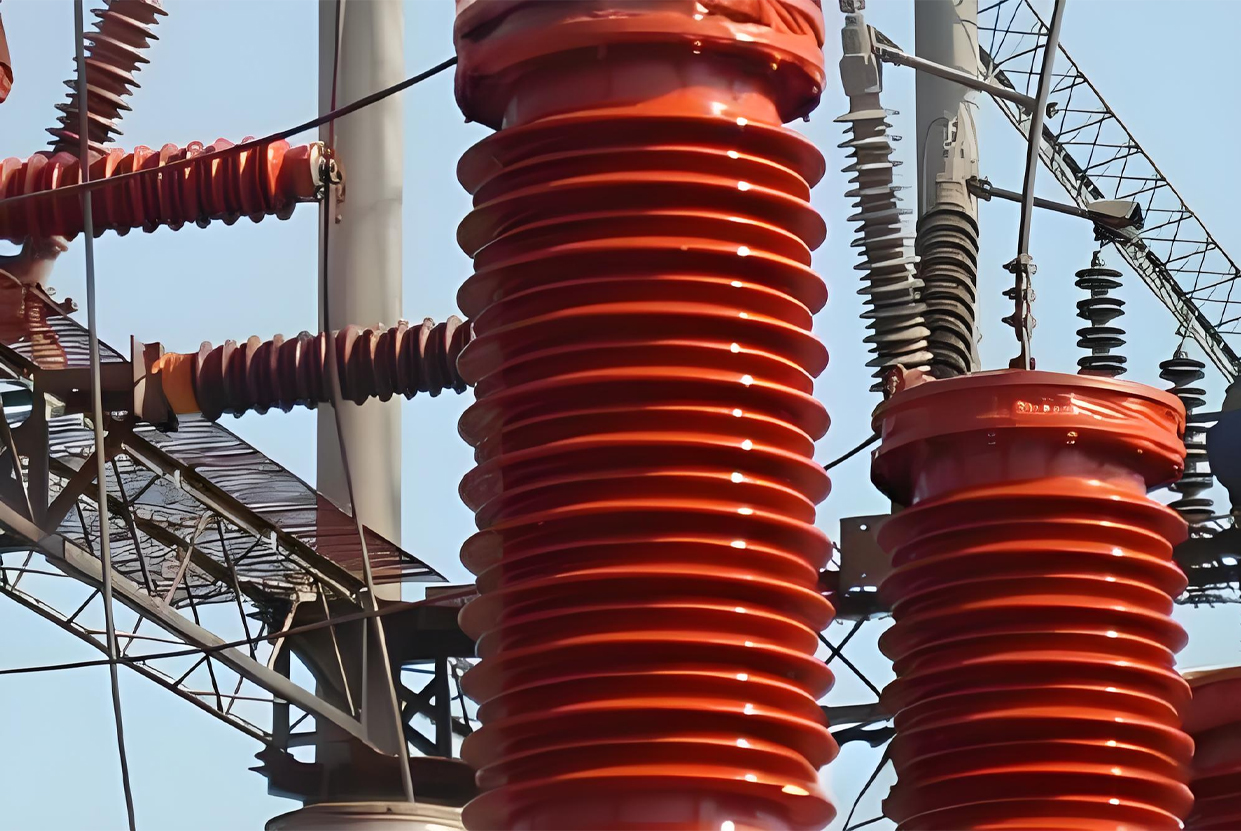

Ukusetshenziswa kwe-silicone kumishini yokudlulisa amandla njengeama-insulatorsfuthiukubamba umbaniisibe yinto esemqoka. Nasi isizathu:

I-Insulation kagesi:

Ama-silicone insulators asiza ukugcina ukuphepha nokusebenza kahle kwezintambo zikagesi ngokuvimbela ukuvuza kukagesi, ngisho nasezimeni zamandla aphezulu. Umshini womjovo we-silicone wesimo esiqinile uqinisekisa ukuthi lawa ma-insulators akhiqizwa ngezindawo eziqondile zokuvala ugesi ezingamelana nezimo zezulu ezimbi kakhulu kanye nengcindezi kagesi.

Ukumelana Nesimo Sezulu:

Ingqalasizinda kagesi kufanele ibekezelele zonke izinhlobo zezinselele zemvelo—ukushisa okukhulu, imvula enamandla, iqhwa, ngisho nemisebe ye-UV evela elangeni. Irabha ye-Silicone, ngenxa yokumelana kwayo nesimo sezulu esihle kakhulu, iyinto ehamba phambili yokuvikela nokuvikela imishini kagesi ezindaweni ezingaphandle. Imishini yokujova iqinisekisa ukuthi lezi zakhiwo zifakwe kuzo zonke izingxenye ezikhiqizwayo.

Amandla Emishini Nokuqina:

Ama-insulators kanye nezinqamuli zombani zidinga ukumelana nezingcindezi eziphezulu zemishini (isb., ukushuba, umthelela) ngaphezu kwengcindezi kagesi. Imishini yomjovo we-silicone yesimo esiqinile iqinisekisa ukuthi i-silicone esetshenzisiwe inobhalansi obufanele bamandla, ukuguquguquka, nokuqina.

Izicelo ku Insulators kanye Lightning Arresters

Ama-Silicone Insulators:

Esetshenziswa emigqeni yamandla kagesi aphezulu kanye neziteshi ezingaphansi, ama-silicone insulators abalulekile ekuvimbeleni ukuvuza kukagesi nokuqinisekisa ukudluliswa kwamandla okuthembekile. Inqubo yokubumba umjovo ikhiqiza ama-insulators anendawo ebushelelezi enciphisa ubungozi bokunqwabelana kokungcola futhi ithuthukise ukusebenza kwawo ngokuhamba kwesikhathi.

Ababambe Umbani:

Izinqamuli zombani zivikela izinto zikagesi emiphumeleni elimazayo yokushaywa umbani nokushaywa kukagesi. Irabha ye-Silicone isetshenziselwa ukugoqa ngaphandle kwalawa madivayisi ngenxa yemvelo yayo engaqhubeki kanye nekhono lokumunca nokuhlakaza amandla amakhulu kagesi. Imishini yomjovo we-silicone yesimo esiqinile ikhiqiza izingxenye zokubopha umbani ezingamelana neziteleka eziqondile kuyilapho ivikela imishini ebalulekile.

Izinzuzo Zokusebenzisa Imishini Yokujova Ye-Silicone Yesifunda Esiqinile Embonini Yamandla

Ukunemba nokuvumelana:

Ngokuzenzakalelayo nokulawula okunembile kwemingcele yomjovo (izinga lokushisa, ingcindezi, isivinini), abakhiqizi bangaqinisekisa ukuthi ingxenye ngayinye ikhiqizwa ngokucaciswa okuqondile, ukuthuthukisa ikhwalithi jikelele nokuthembeka.

Ukusebenza Kakhulu Kokukhiqiza:

Inqubo yokubumba umjovo iyashesha futhi ingakhiqiza izingxenye ezinkulu zezingxenye ezinokulahlwa okuncane, okusiza ukunciphisa izindleko zokukhiqiza nesikhathi.

Ukwenza ngokwezifiso:

Izinto zamandla ezihlukene zidinga umumo, osayizi abahlukene, nezici zokusebenza. Imishini yomjovo we-silicone yesimo esiqinile ingashintshwa kalula ukuze yenze isikhunta sangokwezifiso sezingxenye ezihlukahlukene, kusukela kuma-seal amancane kuya kuma-insulators amakhulu.

Ukusebenza Kwamandla:

Imishini yesimanje yokujova iklanyelwe ukonga amandla, yehlise i-carbon footprint yezinqubo zokukhiqiza.

Isiphetho

Imishini yomjovo we-silicone yesifunda esiqinile ishintsha indlela esikhiqiza ngayo izingxenye ezibalulekile embonini yamandla. Ngokuqinisekisa ukukhiqizwa okunembayo kwama-insulators asebenza kahle kakhulu nezivimbela umbani, le mishini isiza ukuvikela ingqalasizinda yethu kagesi ezingozini zemvelo nezikagesi. Njengoba imboni yamandla iqhubeka ikhula futhi ithuthuka, le mishini izodlala indima ebalulekile ekuqinisekiseni ukuthi amagridi ethu aphephile, athembekile, futhi aqinile—manje nasesikhathini esizayo.

Uma usembonini yamandla noma ubandakanyeka ekukhiqizeni izingxenye zikagesi, ukuqonda ukubaluleka kwemishini yokujova i-silicone yesimo esiqinile kungakusiza wenze izinqumo ezinolwazi mayelana nobuchwepheshe obushayela imikhiqizo esithembele kuyo nsuku zonke.

Isikhathi sokuthumela: Jan-03-2025