Isingeniso

Ukubumba umjovo wepulasitiki nenjoloba kunesikhundla esibalulekile embonini yesimanje yokukhiqiza. Kungakhathaliseki ukuthi yimikhiqizo yepulasitiki evamile ekuphileni kwansuku zonke, noma imikhiqizo yenjoloba esetshenziswa kabanzi emkhakheni wezimboni, ubuchwepheshe bokubumba umjovo budlala indima ebalulekile. Lesi sihloko sihlose ukuhlolisisa umehluko phakathi kokubumba komjovo wepulasitiki nenjoloba ukusiza abafundi baqonde kangcono lezi zinqubo ezimbili ezibalulekile zokukhiqiza.

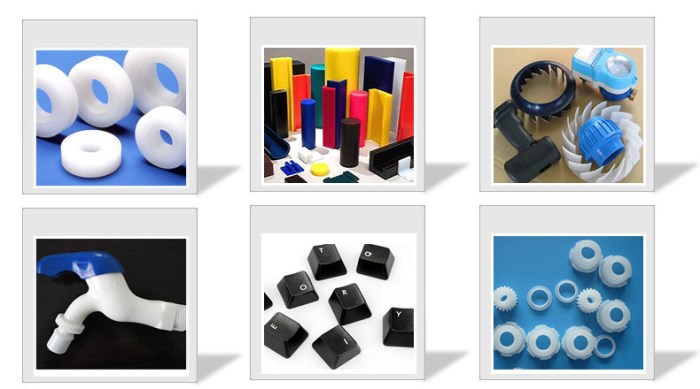

Ukubumba umjovo wePlastiki kuyinqubo lapho ipulasitiki encibilikisiwe ijova esikhunjeni, esipholiswa futhi siqiniswe ukuze sakhe umkhiqizo othile womumo. Ngokwezibalo, inani lemikhiqizo yepulasitiki ekhiqizwa ukubunjwa komjovo wepulasitiki emhlabeni likhulu minyaka yonke. Isibonelo, izinto eziningi zepulasitiki ezisetshenziswa abakhiqizi bezimoto, njengezingxenye zangaphakathi, ama-bumpers, njll., zenziwa ngokubunjwa komjovo wepulasitiki.

Ukubumba umjovo wenjolobaukujova izinto zenjoloba esikhunjeni, emva kokuvuthwa nezinye izinqubo, ukwenza imikhiqizo yenjoloba ehlukahlukene. Imikhiqizo yenjoloba nayo isetshenziswa kabanzi kwezezimoto, emishinini, kweye-elekthronikhi nakweminye imikhakha. Isibonelo, amathayi emoto, ama-seal, njll., imikhiqizo ejwayelekile yokubumba umjovo wenjoloba.

Ukubaluleka kwezinqubo ezimbili zokubumba umjovo akukhona nje ukuthi zingakwazi ukukhiqiza ngokuphumelelayo imikhiqizo enezimo eziyinkimbinkimbi, kodwa futhi zingaqinisekisa ukunemba kanye nekhwalithi yemikhiqizo. Ngokulawula ngokunembile amapharamitha afana nezinga lokushisa, ingcindezi kanye nesikhathi ngesikhathi sokujova, imikhiqizo enembayo ephezulu nekhwalithi enhle yendawo ingakhiqizwa. Ngesikhathi esifanayo, lezi zinqubo ezimbili nazo zinezinzuzo zokusebenza kahle kokukhiqiza kanye nezindleko eziphansi, futhi zingahlangabezana nezidingo zokukhiqiza okukhulu.

Uhlolojikelele lokubumba umjovo wepulasitiki

(1) inqubo yenqubo nokugeleza

Umgomo wenqubo wokubumba umjovo wepulasitiki ukufaka izinto ezingavuthiwe zepulasitiki eziyimbudumbudu noma eziyimpuphu ku-hopper yomshini womjovo, izinto ezingavuthiwe ziyashiswa futhi zincibilike esimweni esigelezayo, ziqhutshwa yisikulufa noma ipiston yomshini womjovo, ngombhobho kanye nohlelo lokuthulula lwesikhunta emgodini wokubumba, futhi lupholile futhi luqiniswe emgodini wokubumba.

Inqubo ethize ngokuyinhloko ihlanganisa lezi zinyathelo ezilandelayo: Okokuqala, ukulungiswa kwempahla eluhlaza, ngokusho kwezidingo zomkhiqizo ukukhetha izinto zokusetshenziswa kwepulasitiki ezifanele, njenge-polystyrene evamile, i-polyethylene, i-polypropylene nokunye. Lezi zinto zokusetshenziswa ngokuvamile zinezici zokusebenza ezihlukile, njengamandla, ukuqina, ukumelana nokushisa, njll., ukuhlangabezana nezidingo zemikhiqizo ehlukene. Khona-ke impahla eluhlaza yengezwa emshinini womjovo wokushisa nokuncibilika, kule nqubo, kuyadingeka ukulawula ngokuqinile izinga lokushisa lokushisa, ngokuvamile, izinto zokusetshenziswa kwepulasitiki ezihlukene zinezigaba ezihlukene zokushisa ezincibilikayo. Isibonelo, izinga lokushisa elincibilikayo le-polyethylene livamise ukuba phakathi kuka-120 ° C -140 ° C, kuyilapho izinga lokushisa elincibilikayo le-polystyrene liba ngu-180 ° C -220 ° C.

Lapho impahla eluhlaza incibilika futhi igeleza, iphushwa yisikulufu noma ipiston yomshini womjovo ingene emgodini wesikhunta ngokusebenzisa umlomo wombhobho kanye nohlelo lokuthulula lwesikhunta. Kule nqubo, ingcindezi yomjovo iyipharamitha eyinhloko, okudingeka ibe mkhulu ngokwanele ukuze inqobe ukumelana nokuncibilika ngesikhathi sokugeleza nokuqinisekisa ukuthi ukuncibilika kungagcwalisa isikhunta. Ngokuvamile, ingcindezi yomjovo ingaba phakathi kwamashumi kuya kumakhulu wempa.

Ekugcineni, esigabeni sokupholisa, ipulasitiki iyapholiswa futhi iqiniswe emgodini wesikhunta ngokusebenzisa uhlelo lokupholisa lwesikhunta. Ubude besikhathi sokupholisa buncike ohlotsheni lwepulasitiki, ubukhulu bomkhiqizo nezinye izici. Ngokuvamile, isikhathi sokupholisa semikhiqizo emincane kakhulu sifushane, esingaba phakathi kwamashumi amasekhondi kanye nemizuzu embalwa; Isikhathi sokupholisa semikhiqizo ewugqinsi sizonwetshwa ngokufanele.

(2) Izici nezinzuzo

Ukubumba umjovo wepulasitiki kunezici eziningi kanye nezinzuzo. Okokuqala, ingenza izimo eziyinkimbinkimbi. Ngenxa yokuthi ipulasitiki ine-fluidity enhle esimweni esincibilikisiwe, ingagcwaliswa ngezimbobo zesikhunta eziyinkimbinkimbi, ukuze ikhiqize imikhiqizo yepulasitiki enobunjwa obuhlukahlukene obuyinkimbinkimbi, njengemikhiqizo enezimbotshana zangaphakathi kanye nezakhiwo ezihlehlayo.

Okwesibili, ukunemba kuphakeme. Ngokulawula ngokunembile amapharamitha afana nezinga lokushisa, ingcindezi kanye nesikhathi phakathi nenqubo yomjovo, imikhiqizo enembayo ephezulu ingakhiqizwa, futhi ukubekezelelana kwe-dimensional kungalawulwa phakathi kwezintambo ezimbalwa kuya kweziningi. Isibonelo, amanye amagobolondo omkhiqizo we-elekthronikhi anembayo angafinyelela izidingo zokunemba okuphezulu ngokubumba umjovo wepulasitiki.

Ngaphezu kwalokho, isikhunta somjovo wepulasitiki sihlukahlukene, silungele izinhlobo ezihlukahlukene zokuhweba zokucubungula. Isikhunta esihlukene somjovo singakhelwa imikhiqizo ehlukene ngokuya ngokuma, usayizi kanye nezidingo zokusebenza. Ngaphezu kwalokho, isikhunta somjovo singakhiqizwa ngobuningi, ngokusebenza kahle kokukhiqiza okuphezulu, futhi silungele izinhlobo ezahlukene zohwebo lokucubungula, njenge-OEM (umkhiqizi wemishini yasekuqaleni) kanye ne-ODM (umkhiqizi womklamo wokuqala).

Ngesikhathi esifanayo, ukubunjwa komjovo wepulasitiki kunezinhlobonhlobo zokuzivumelanisa nezimo. Ingasetshenziselwa ukukhiqiza imikhiqizo ehlukahlukene yepulasitiki, kusukela ezidingweni zansuku zonke ezifana ne-tableware, amathoyizi, emikhiqizweni yezimboni efana nezivalo zikagesi, izingxenye zezimoto nokunye. Ngokwezibalo, cishe u-70% wemikhiqizo yepulasitiki yomhlaba ikhiqizwa ngokubumba umjovo.

Uhlolojikelele lomshini wokubumba umjovo wenjoloba

(1) inqubo yenqubo nokugeleza

Umshini wokubumba umjovo wenjolobaiwuhlobo lobuchwepheshe bokucubungula obuthumela izinto ekubunjweni kokwenza ngokusebenzisa i-extruder yenjoloba esebenza kahle kakhulu, futhi ngemva kokucindezela okuthile kanye nezinga lokushisa, izinto zokusetshenziswa kwenjoloba zakha isimo esidingekayo nosayizi esikhunjeni.

Inqubo ethize imi kanje:

Umsebenzi wokulungiselela: kufaka phakathi ukuhlolwa kwerabha eluhlaza, ukomisa, ukushisa kwangaphambili kanye neminye imisebenzi, kanye nokwakhiwa kwesikhunta, ukukhiqiza kanye nokulungisa iphutha. Ukuhlolwa kwezinto ezisetshenziswayo zenjoloba kubalulekile ukuze kuqinisekiswe ukuthi ikhwalithi nokusebenza kwezinto ezingavuthiwe kuhlangabezana nezidingo zemikhiqizo. Isibonelo, kweminye imikhiqizo yenjoloba esebenza kahle kakhulu, njengamathayi ezimoto, ama-seal, njll., kuyadingeka ukukhetha izinto ezisetshenziswayo zerabha ezisezingeni eliphezulu ukuze kuqinisekiswe amandla, ukumelana nokugqoka kanye nokumelana nokuguga kwemikhiqizo. Enqubweni yokomisa nokushisa, izinga lokushisa kanye nesikhathi kufanele kulawulwe ngokuqinile ukuze kugwenywe ukomiswa ngokweqile noma ukushisisa okwanele kwezinto zokusetshenziswa kwerabha. Ukuklama nokukhiqizwa kwesikhunta kudinga ukuklanywa ngokucophelela ngokuvumelana nokuma, ubukhulu kanye nezidingo zokusebenza komkhiqizo ukuze kuqinisekiswe ukunemba kanye nekhwalithi yesikhunta.

Ukukhiqizwa kwezinto ezibonakalayo: Izinhlayiya zenjoloba ezomile zengezwa ku-extruder yenjoloba, futhi impahla iphathwa ngaphambilini ngochungechunge lwezinqubo ezifana nokushisa nokukhipha. Kule nqubo, ukusebenza kanye nepharamitha Izilungiselelo ze-rubber extruder zibaluleke kakhulu. Isibonelo, izinga lokushisa le-extruder, isivinini se-screw kanye neminye imingcele izothinta ngokuqondile umphumela we-plasticizing kanye nekhwalithi yezinto zenjoloba. Ngokuvamile, izinga lokushisa le-extruder lingaba phakathi kuka-100 ° C no-150 ° C, futhi isivinini se-screw singaba phakathi kwamashumi kuya kumakhulu ama-revolutions ngomzuzu, futhi imingcele ethile kufanele ilungiswe ngokuvumelana nezidingo zohlobo nokusebenza kwento yerabha.

Ukubumba: Izinto zenjoloba ezilashwe ngaphambili zifakwa esikhunjini ngomshini womjovo wenqubo yokubumba. Ngalesi sikhathi, ingcindezi ethile kanye nezinga lokushisa kudingeka kuxhunywe ukuze kwenziwe injoloba eluhlaza yakha umkhiqizo womumo nosayizi oyifunayo. Ukucindezela kanye nezinga lokushisa enkambweni yokubumba kuyimingcele eyinhloko, ingcindezi ingaba phakathi kwamashumi kuya kumakhulu we-mpa, futhi izinga lokushisa lingaba phakathi kuka-150 ° C no-200 ° C. Imikhiqizo yenjoloba ehlukene inezidingo ezahlukene zokucindezela nokushisa, isibonelo, kweminye imikhiqizo emikhulu yenjoloba, njengezikrini zenjoloba, i-bridge shock absorbers, njll.

Ukunciphisa ukucindezela: Ngemva kokuqedwa kokubumba, kuyadingeka ukupholisa phansi nokudiliza ukuze kukhishwe imikhiqizo yenjoloba ekubunjweni. Inqubo yokupholisa kufanele yenziwe kancane ukugwema ukuguquguquka noma ukuqhekeka kwemikhiqizo ngenxa yokushintsha kwezinga lokushisa ngokushesha. Qaphela lapho ususa ukuze ugweme ukulimaza umkhiqizo.

(2) Izici nezinzuzo

Umthamo wokukhiqiza owodwa: umthamo wokukhiqiza owodwa womshini wokubumba umjovo wenjoloba ngokuvamile uphakathi kwamashumi amagremu namakhilogremu amaningana, okuthuthukisa kakhulu ukukhishwa kwemikhiqizo eqediwe.

Ukunemba okuphezulu komkhiqizo: Umshini wokubumba umjovo wenjoloba ungalawula ngokunembile izinga lokushisa, ingcindezi kanye neminye imingcele yezinto ngesikhathi sokubumba, ngaleyo ndlela uthuthukise kakhulu ukunemba komkhiqizo.

Umjikelezo omfushane wokubumba: Ngoba ukubumba umjovo wenjoloba kungakha imikhiqizo eminingi ngesikhathi esisodwa, futhi umthamo wokukhiqiza mkhulu, umjikelezo wokubumba umfushane. Isibonelo, ekukhiqizeni ezinye izingxenye zezimoto, ukusetshenziswa kwenqubo yokubumba umjovo wenjoloba kungathuthukisa kakhulu ukusebenza kahle kokukhiqiza futhi kufinyeze umjikelezo wokukhiqiza.

Ikhwalithi ephezulu yomkhiqizo oqediwe: ukubumba umjovo wenjoloba kunganciphisa umkhiqizo ngenxa yokwakheka okungalingani, ama-bubbles nezinye izinkinga, ukuze izinga lomkhiqizo lithuthuke kakhulu. Isibonelo, izigxivizo zezimoto ezikhiqizwa inqubo yokubumba umjovo wenjoloba zinokuvaleka okuhle nokumelana nokugqokwa, okungathuthukisa ngempumelelo ukusebenza nempilo yesevisi yezimoto.

Umehluko phakathi kokubumba komjovo wepulasitiki nenjoloba

(1) Umehluko ezicini zempahla eluhlaza

Izinto ezingavuthiwe zepulasitiki ngokuvamile ziyi-thermoplastic noma i-thermosetting resin, enobulukhuni obuphezulu nokuqina, futhi izinto zokusetshenziswa zepulasitiki ezihlukene zinezici zokusebenza ezihlukene, njengamandla, ukuqina, ukumelana nokushisa nokunye. Isibonelo, i-polyethylene inokumelana okuhle kwamakhemikhali kanye nokufakwa kukagesi, kodwa amandla ayo nokumelana nokushisa kuphansi kakhulu; I-Polystyrene inokucaca okuphezulu nobulukhuni, kodwa i-brittle. Lezi zici zinquma ukuthi ipulasitiki idinga izinga lokushisa elithile kanye nebanga lokucindezela ngesikhathi sokubunjwa komjovo ukuze kuqinisekiswe ukuthi impahla eluhlaza ingancibilika ngokugcwele futhi igcwalise isikhunta.

Impahla eluhlaza yerabha irabha yemvelo noma irabha yokwenziwa, enokuqina okuphezulu nokuguquguquka. Irabha ivamise ukuthamba futhi kulula ukonakala esimweni esingavuthisiwe, kuyilapho inamandla aphakeme futhi imelana nokugqoka ngemva kokuvuvuka. Izakhiwo ezinwebekayo zenjoloba zenza kube kudingekile ukucabangela izinga lokuncipha kanye nokuqina kwempahla enqubweni yokubumba umjovo ukuze kuqinisekiswe ukunemba kwe-dimensional nokuzinza komumo womkhiqizo. Isibonelo, lapho uklama isikhunta semikhiqizo yenjoloba, kubalulekile ukucabangela ukuthi izinga lokushwabana kwenjoloba likhulu, ngokuvamile liphakathi kuka-1% -5%, kanti izinga lokushwabana kwepulasitiki ngokuvamile liphakathi kuka-0.5% no-2%.

(2) Umehluko kumapharamitha wenqubo

Mayelana nezinga lokushisa, izinga lokushisa lokubunjwa komjovo wepulasitiki livame ukuba phezulu, futhi izinto zokusetshenziswa zepulasitiki ezihlukene zinezigaba zokushisa ezincibilikayo ezihlukene. Isibonelo, izinga lokushisa elincibilikayo le-polyethylene livame ukuba phakathi kuka-120 ° C no-140 ° C, futhi izinga lokushisa elincibilikayo le-polystyrene lingaba ngu-180 ° C no-220 ° C. Izinga lokushisa lokubunjwa komjovo wenjoloba liphansi kakhulu, ngokuvamile liphakathi kuka-100 ° C no-200 ° C, futhi izinga lokushisa elithile lincike ohlotsheni kanye nokusebenza kwerabha. Isibonelo, izinga lokushisa le-vulcanization lerabha yemvelo ngokuvamile liphakathi kuka-140 ° C no-160 ° C, futhi izinga lokushisa le-vulcanization lerabha yokwenziwa lingase lihluke.

Mayelana nengcindezi, ukubumba komjovo wepulasitiki kudinga ingcindezi ephezulu yomjovo, ngokuvamile ephakathi kwamashumi kuya kumakhulu wempa, ukuze kunqobe ukumelana nokuncibilika ohlelweni lokugeleza nokuqinisekisa ukuthi ukuncibilika kungagcwalisa imbobo yesikhunta. Ingcindezi yokubumba umjovo wenjoloba iphansi kakhulu, ngokuvamile iphakathi kwamashumi kuya kumakhulu ama-mpa, kodwa kweminye imikhiqizo emikhulu yenjoloba, kungase kudingeke ingcindezi ephezulu. Isibonelo, lapho ukhiqiza imikhiqizo emikhulu yerabha efana nezikrini zezigubhu zenjoloba kanye nezinto zokudonsa ibhuloho, ukucindezela okuphezulu kuyadingeka ukuze kuqinisekiswe ikhwalithi yokubumba yemikhiqizo.

(3) Umehluko ezicini zomkhiqizo

Ngokuphathelene nokuma, ukubunjwa komjovo wepulasitiki kungakhiqiza imikhiqizo ehlukahlukene enezimo eziyinkimbinkimbi, njengemikhiqizo yepulasitiki enezimbotshana zangaphakathi, izakhiwo ezihlehlayo, njll. Ngenxa yokuqina kwayo okuphezulu nokuguquguquka, imikhiqizo yenjoloba ngokuvamile ilula ngokuma, ikakhulukazi ama-seal, amathayi nokunye.

Ngokuphathelene nokunemba, ukubumba komjovo wepulasitiki kungakhiqiza imikhiqizo enembayo ephezulu, futhi ukubekezelelana kwe-dimensional kungalawulwa phakathi kwezintambo ezimbalwa kanye nenqwaba yezintambo. Ukunemba kwemikhiqizo yokubumba umjovo wenjoloba iphansi kakhulu, kodwa kweminye imikhiqizo yenjoloba esebenza kahle kakhulu, njengezigxivizo zezimoto, njll., ingafinyelela nezimfuneko zokunemba okuphezulu.

Mayelana nokusetshenziswa, imikhiqizo yepulasitiki isetshenziswa kabanzi ezidingweni zansuku zonke, imikhiqizo yezimboni kanye neminye imikhakha, njenge-tableware, amathoyizi, igobolondo likagesi, izingxenye zezimoto nokunye. Imikhiqizo yenjoloba isetshenziswa kakhulu ezimotweni, emishinini, kweze-elekthronikhi nakweminye imikhakha, njengamathayi, ama-seal, ama-shock absorbers nokunye.

Isiphetho

Kunomehluko osobala phakathi kokubunjwa komjovo wepulasitiki nenjoloba ezicini zempahla eluhlaza, imingcele yenqubo kanye nezici zomkhiqizo.

Ngokombono wezici zempahla eluhlaza, izinto zokusetshenziswa zepulasitiki ngokuvamile ziyi-thermoplastic noma i-thermosetting resins, enobulukhuni obuphezulu nokuqina, futhi amapulasitiki ahlukene anezakhiwo ezahlukene. Impahla eluhlaza yerabha irabha yemvelo noma irabha yokwenziwa, enokuqina okuphezulu nokuguquguquka.

Ngokuphathelene nemingcele yenqubo, izinga lokushisa lokubumba umjovo wepulasitiki liphakeme, izinga lokushisa elincibilikayo lamapulasitiki ahlukene lihlukile, futhi ingcindezi yomjovo iphakeme ukuze kuqinisekiswe ukuthi ukuncibilika kugcwele umgodi wokubumba. Izinga lokushisa lomjovo wenjoloba liphansi uma kuqhathaniswa, ingcindezi nayo iphansi, kodwa imikhiqizo yenjoloba emikhulu ingadinga ingcindezi ephakeme.

Izici zomkhiqizo, ukubunjwa komjovo wepulasitiki kungenza imikhiqizo yesimo esiyinkimbinkimbi, ukunemba okuphezulu, okusetshenziswe kabanzi empilweni yansuku zonke kanye nezimboni zezimboni. Ngenxa yokunwebeka okuphakeme, imikhiqizo yenjoloba ngokuvamile ilula ngokuma futhi incane ngokunemba, kodwa imikhiqizo yenjoloba esebenza kahle kakhulu ingahlangabezana nezidingo zokunemba okuphezulu, ikakhulukazi ezisetshenziswa ezimotweni, emishinini, ezikagesi nakweminye imikhakha.

Lezi zinqubo ezimbili zokubumba umjovo zibalulekile ezimbonini ezihlobene. Embonini yemikhiqizo yepulasitiki, ukubumba umjovo wepulasitiki kusebenza kahle, izindleko eziphansi, kungahlangabezana nezidingo zokukhiqiza okukhulu, futhi kuhlinzeka ngemikhiqizo ehlukahlukene ecebile emikhakheni ehlukahlukene. Embonini yemikhiqizo yenjoloba, umthamo owodwa wokukhiqiza wokubumba umjovo wenjoloba mkhulu, ukunemba komkhiqizo kuphakeme, umjikelezo wokubumba mfushane, futhi umkhiqizo oqediwe usezingeni eliphezulu, ohlinzeka ngezingxenye ezibalulekile nezigxivizo neminye imikhiqizo yezimoto, imishini nezinye izimboni, okuqinisekisa ukuthuthukiswa okuzinzile kwalezi zimboni. Ngamafuphi, ukubumba komjovo wepulasitiki nenjoloba kudlala indima engenakushintshwa ekukhiqizeni kwesimanje, futhi izici nezinzuzo zazo ezihlukene nazo zinikeza ukwesekwa okuqinile ekuthuthukisweni kwezimboni ezahlukene.

Isikhathi sokuthumela: Nov-08-2024